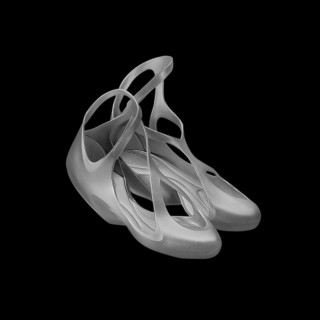

- Manufacturer: Melissa Plastic Dreams

- Designer: Zaha Hadid

- Material: Melflex R

- www.melissaplasticdreams.com

Index

- Architect 'The first woman to win the Pritzker Prize for Architecture in its 26 year history, Zaha Hadid (1950-) has defined a radically new approach to archite

- Form The search of innovative geometry has been during the last years an interesting subject for Contemporary Architecture. As the 21st century brought a n

- Manufacturer Zaha Hadid's recent work on the Chanel Mobile Art project seems to have sparked a desire for further fashion collaboration. This time, the Brazilian f

- Recycling Recycling involves processing used materials into new products to prevent waste of potentially useful materials, reduce the consumption of fresh raw m

- Production The theory of injection moulding can be reduced to four simple individual steps: Plasticizing, Injection, Chilling, and Ejection. Each of those steps

- Waste 'Plastic Island - Twice the Size of Texas & Growing' Import / Export In 2008, 8,923 tonnes of plastic shoes were imported into Sweden, at a value of a

'The first woman to win the Pritzker Prize for Architecture in its 26 year history, Zaha Hadid (1950-) has defined a radically new approach to architecture'

The opening words of the citation when Zaha Hadid was named as the first woman to win the prestigious Pritzker Prize for architecture in 2004 were, 'Her architectural career has not been traditional or easy.' An understatement. All architects have to struggle, but Hadid seems to have struggled rather more than most. Her single-mindedness, her singular lack of compromise is the stuff of legend although, as one writer commented, like a hurricane, 'the storms are all on the outside.' In part, it is simple artistic temperament, necessary, perhaps, to create forceful architecture like Hadid's. […]

Hadid's architecture denies its own solidity. Short of creating actual forms that morph and change shape – still the stuff of science fiction – Hadid creates the solid apparatus to make us perceive space as if it morphs and changes as we pass through. Perhaps wisely, she talks little about theory. Unlike, say, Daniel Libeskind, she does not say that a shape symbolises this or that. And she wears her cultural identity lightly. […]

Scale

Architects love to dabble on projects of smaller scales, and now iconic architect Zaha Hadid is joining the ranks of architect-dabblers by announcing her foray into shoe design! The always provocative architect is someone we love to criticise here at Inhabitat for her obsessive formalism, but we must say that we are thrilled to see her burgeoning interest in sustainable design take the form of a partnership with Brazilian eco shoe design company Melissa.

The search of innovative geometry has been during the last years an interesting subject for Contemporary Architecture. As the 21st century brought a new era for architectural design, CAD programs have evolved together with the idea of Form Finding. The possibilities offered make the collaboration of the architect with the computer now possible in terms of searching the appropriate form for given cases.

As the analysis of contemporary architectural pieces has indicated, the procedure of architectural design can be semi-automated. Parametric Form Finding, meaning the procedure followed offering solutions to spatial problems by using changeable variables, is transferring generative approaches into the architectural design workflow by introducing a set of rules to describe the constraints of the form. Given this context, two methods have been realized, which are guided by the user by providing basic two dimensional shapes, restrictions and form characteristics. The approach is fitted in a plug-in for the modeling environment of Rhinoceros that generates three dimensional form based on the user's input.

Parameters

We did one [research project] with biological systems, organisms, from the microscopic to the macroscopic. So we have these kinds of inputs; then it stays in the repertoire. There's also mathematics – new mathematics – topological patterns and also what is having an impact is new modelling tools and more recently parametric modelling, parametric fields and scripted fields, you get a new sensibility with respect to orders of iteration. It fits quite well but it still feels quite continuous with the earliest works.

Looking through these new tools there's a kind of intricacy of overall arrangement with a very high degree of coherence. There's a lot of internal laws of correlation; everything relates to everything else. It's a continuous change but it all fits together. It's not like a garbage heap. It's not random or arbitrary.

And these new tools bring this to a new level on a new scale […] we were able to enter the domain of urbanism under the heading of 'parametric urbanism'. We're creating whole fields of buildings and territories. We created an urban geometry of street patterns and a kind of morphology, urban morphology that is highly differentiated. [...]

www.youtube.com/watch?v=IksIyui84wEZaha Hadid's recent work on the Chanel Mobile Art project seems to have sparked a desire for further fashion collaboration. This time, the Brazilian footwear brand Melissa has given Hadid the opportunity to design a shoe. Melissa, a company which uses sustainable materials, has already collaborated with Vivienne Westwood, Judy Blame and Alexandre Herchcovitch.

Sustainability

The Brazilian brand, Melissa, has been active on the market for nearly three decades and is recognised around the world for its innovative work in plastics. Sustainable development is a cornerstone of their work and is key to their economic development. Melissa understands that we need to protect natural resources for future generations, and therefore, they have adopted rules to guarantee the sustainability of all its factories and to produce without damaging the environment. To this end, Melissa utilizes sustainability concepts from the inception of an idea to the production of the final product. All outcomes are created, developed, fabricated and distributed with a rigid control to their life cycle. Because their products are created from mono-materials they can be easily disassembled and recycled. 100% of materials are used in production; solid, liquid and gas residues, left over from the production process are recycled and dealt with in-house. Nothing leaves the factory without being properly treated, resulting in practically zero waste.

Melissa believes that harmony within business, society and the environment is the most ethical way to respect consumers and the market.

Material

Melissa Shoes are made from 'Melflex' plastic, a patented, hypo-allergenic, recyclable, and extremely flexible PVC. The shoes are totally cruelty free and devoid of animal products. The Brazilian-based company is totally rad in its recycling of 99.9% of factory water and waste, and they also go the distance by recycling overstock styles into next season's collection. […] Melissa Shoes employees are paid above average wages and benefits. What's not to like in these plastic fantastic accessories? What a fabulous way to traipse and tromp through spring rain puddles, or consider wearing Melissa Shoes on your next urban eco-adventure and watch heads turn with total green envy!

Recycling involves processing used materials into new products to prevent waste of potentially useful materials, reduce the consumption of fresh raw materials, reduce energy usage, reduce air pollution (from incineration) and water pollution (from land filling) by reducing the need for 'conventional' waste disposal, and lower greenhouse gas emissions as compared to virgin production. [...]

Plastic

The confusion over what we can and cannot recycle continues to confound consumers. Plastics are especially troublesome, as different types of plastic require different processing to be reformulated and re-used as raw material. Some municipalities accept all types of plastic for recycling, while others only accept jugs, containers and bottles with certain numbers stamped on their bottoms.

Melflex

For years now, the biggest challenge has been to develop a material which could be easily moulded to the foot, providing superior comfort in relation to other products currently on the market. This formula was developed in Melissa's laboratories. The result is a composition called 'Melflex'. This material has characteristics which provide improved elasticity, impermeability and resistance.

The theory of injection moulding can be reduced to four simple individual steps: Plasticizing, Injection, Chilling, and Ejection. Each of those steps is distinct from the others and correct control of each is essential to the success of the total process.

- Plasticising

Describes the conversion of the polymer material from its normal hard granular form at room temperatures, to the liquid consistency necessary for injection at its correct melt temperature.

- Injection

The stage during which this melt is introduced into a mould to completely fill a cavity or cavities.

- Chilling

The action of removing heat from the melt to convert it from a liquid consistency back to its original rigid state. As the material cools, it also shrinks.

- Ejection

The removal of the cooled, moulded part from the mould cavity and from any cores or inserts.

Repetition of these basic steps in sequence is the process of injection moulding.

www.youtube.com/watch?v=1-WjM0it9jIEnvironmental Impact

At first glance, injection moulding may appear to be a relatively benign process with respect to the environment due to its low direct emission levels and apparently low energy consumption. However, when calculating the environmental cost of injection moulding one must also take into account the ancillary processes and raw materials used in the process. Aside from the raw material production stage which has substantial emissions, the main metric in the whole injection moulding process is energy consumption. The large scale of the injection moulding industry makes the environmental impacts of this process especially critical. In other words, a small increase in the efficiency of the process could lead to substantial savings for the environment.

'Plastic Island - Twice the Size of Texas & Growing'

Import / Export

In 2008, 8,923 tonnes of plastic shoes were imported into Sweden, at a value of almost SEK 1 billion. This represents an increase of more than 55% over ten years. The majority of shoes in this specific category were imported from China, which was responsible for 5,438 tonnes in 2008. This is almost half of all the plastic shoes that were imported to Sweden. Imports of shoes from China to Sweden have increased by almost 800% over the past 10 years.

The Great Pacific Garbage Patch

The Great Pacific Garbage Patch, also described as the Eastern Garbage Patch or the Pacific Trash Vortex, is a gyre of marine litter in the central North Pacific Ocean located roughly between 135° to 155°W and 35° to 42°N and estimated to be twice the size of Texas. The patch is characterized by exceptionally high concentrations of suspended plastic and other debris that have been trapped by the currents of the North Pacific Gyre. Despite its size and density, the patch is not visible from satellite photography because it consists of very, very small pieces, almost invisible to the naked eye and most of its contents are suspended beneath the surface of the ocean. [...]

An estimated 80% of the garbage comes from land-based sources, and 20% from ships. A typical 3,000 passenger cruise ship produces over eight tons of solid waste weekly, much of which ends up in the patch. Pollutants range in size from abandoned fishing nets to micro-pellets used in abrasive cleaners. Currents carry debris from the west coast of North America to the gyre in about five years, and debris from the east coast of Asia in a year or less. An international research project led by Dr. Hideshige Takada of Tokyo University studying plastic pellets, or nurdles, from beaches around the world may provide further clues about the origins of pelagic plastic.