- Manufacturer: KUKA Automation + Robotics

- Designer: Mario Selic

- Dimensions: 113 × 92 × 47 cm

- www.kuka-robotics.com

Index

- Manufacturer KUKA Robotics is a leading German producer of industrial robots for a variety of industries - from automotive and fabricated metals to food and plasti

- Designer Industrial designer Mario Selic has been contributing to the successful design of KUKA robots for many years. 'I considered the expectations placed o

- History The acclaimed Czech playwright Karel Capek (1890-1938) made the first use of the word ‘robot’, from the Czech word for forced labour or serf. 'It is w

- Biomimicry The practice of developing sustainable human technologies inspired by nature. Sometimes called Biomimetics or Bionics, it's basically biologically ins

- The Three Laws In science fiction, the Three Laws of Robotics are a set of three rules written by Isaac Asimov, which almost all robots appearing in his fiction must

- Ethics The government of South Korea is drawing up a code of ethics to prevent human abuse of robots - and vice versa. The South Korean charter, which may in

- Jobs In the future robots will take over many tasks performed by workers today potentially leading to increased unemployment, says Marshall Brain, founder

- Fears At a conference, held behind closed doors in Monterey Bay, California, leading researchers warned that mankind might lose control over computer-based

- Economics Japan already has robot cleaners and teachers, but now they have been brought in to cook noodles for hungry workers. The mechanical chefs dole out nea

- Good / Bad If it is very difficult for a human to make the killing decision in combat, how can a robot ever be trusted to decide? Unless the robot patrols a blac

KUKA Robotics is a leading German producer of industrial robots for a variety of industries - from automotive and fabricated metals to food and plastics. The company name, KUKA, is an acronym for Keller und Knappich Augsburg. The company was founded in 1898. In 1973 KUKA created the world's first industrial robot with six electromechanically driven axes, known as FAMULUS. By 2006, the KUKA Robotics Corporation and its subsidiaries had installed close to 80,000 robots and the company has become one of the worldwide market leaders in industrial robots. KUKA industrial robots are used in production by companies like: GM, Chrysler, Ford, Porsche, BMW, Audi, Mercedes-Benz, Volkswagen, Ferrari, Harley-Davidson, Boeing, Siemens, IKEA, Swarovski, Wal-Mart, Budweiser, BSN Medical as well as Coca-Cola and others.

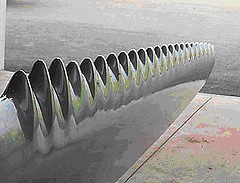

The new KUKA KR 5 arc rounds off the range of KUKA robots at the lower end. Its payload of 5kg makes it outstandingly well-suited to standard arc welding tasks. With its attractive price and compact dimensions, it is the ideal choice for your application too. Whether mounted on the floor or inverted overhead, the KR 5 arc always performs its tasks reliably.

Weight: 127 kg

Mounting positions: floor, ceiling

Suitable for these applications: arc welding, other welding purposes, soldering, painting, surface treatment, other applications.

After consultation with KUKA (other potential applications): Handling, loading and unloading, laser welding, packaging and order picking, other handling operations, and handling for other machines.

www.youtube.com/watch?v=98aDUQDmUjcAs Kuka celebrates its 35th anniversary in the UK, the European robot manufacturer has won another accolade for the Titan six-axis industrial robot. The giant robot, which has a 1000kg payload capacity and reach of more than 4m, has been awarded a prestigious Red Dot Award for Product Design.

Industrial designer Mario Selic has been contributing to the successful design of KUKA robots for many years.

'I considered the expectations placed on an industrial robot: it should be strong, but at the same time fast and agile. Like an athlete. I also felt, however, that it had never really been possible to see this performance and ability in industrial robots just by looking at them. I wanted to change that … Incidentally; design does not necessarily mean higher prices. Functional or intelligent design reduces costs, as superfluous parts are omitted … It should be designed in such a way that people are prepared to work closely with it.'

The acclaimed Czech playwright Karel Capek (1890-1938) made the first use of the word ‘robot’, from the Czech word for forced labour or serf.

'It is with horror, frankly, that he rejects all responsibility for the idea that metal contraptions could ever replace human beings, and that by means of wires they could awaken something like life, love, or rebellion. He would deem this dark prospect to be either an overestimation of machines, or a grave offence against life.'

Universal Automation

In 1948, George Devol and Joe Engelberger invent the first programmable robot arm and coined the phrase Universal Automation for the first time.

The practice of developing sustainable human technologies inspired by nature. Sometimes called Biomimetics or Bionics, it's basically biologically inspired engineering.

Whalepower Wind Turbine: Inspired by the flippers humpback whales use to enable their surprising agility in the water. [...] Compared to smooth surface fins, the bumpy humpback ones have 32% less drag and an 8% increased lift in their movement through air or water. Using such blades to catch the wind as communities and nations switch to renewable sources could provide a 20% increase in efficiency that will help to make wind power generation fully competitive with other alternatives.

In science fiction, the Three Laws of Robotics are a set of three rules written by Isaac Asimov, which almost all robots appearing in his fiction must obey.

- A robot may not injure a human being, or, through inaction, allow a human being to come to harm.

- A robot must obey the orders given it by human beings except where such orders would conflict with the First Law.

- A robot must protect its own existence as long as such protection does not conflict with the First or Second Law.

The government of South Korea is drawing up a code of ethics to prevent human abuse of robots - and vice versa. The South Korean charter, which may include guidelines for the robots themselves, could be seen as a nod to Isaac Asimov's Three Laws of Robotics.

Robot researchers, however, say that Asimov's laws - and the South Korean charter - belong in the realm of science-fiction and are not yet applicable to their field.

South Korea boasts one of the world's most high-tech societies. The country's Ministry of Information and Communication is working on plans to put a robot in every South Korean household by 2020.

The European Robotics Research Network is also drawing up a set of guidelines on the use of robots.

In the future robots will take over many tasks performed by workers today potentially leading to increased unemployment, says Marshall Brain, founder of How Stuff Works and author of e-book Robotic Nation.

'In theory we should all be able to go on a perpetual vacation as robots do all the work,' Brain told attendees in a presentation at the Singularity Summit in San Jose. 'Instead because of the way the economy is structured right now, when robots arrive it will have devastating effects on all of us because there will be so many unemployed people.'

The idea provoked a question from attendees. When industrialization first occurred there were fears of massive unemployment, which never panned out. Why will the integration of robots into the workforce be any different?

Recession times have proved a harsh reality check for Japan's ongoing love affair with robots. Novelty robots have fared the worst, unsurprisingly, as cute or quirky represents the first to go when consumers check their wallets. But even the 370,000 industrial robot workers - the most of any nation - toiling away tirelessly in Japanese factories have seen a sharp drop in demand that mirrors Japan's 40% overall decline in industrial production.

For us squishy types, there's a slight upside to the grim statistics - the analyst added that employers are eliminating robots first in order to protect the jobs of human workers.

As production in the United States evolves to include more machines, programming, and robots, will that have a negative long-term impact on unemployment? Economist Greg Clark says yes, and recent evidence suggests that it may already be happening.

The economic problems of the future will not be about growth but about something more nettlesome: the ineluctable increase in the number of people with no marketable skills, and technology's role not as the antidote to social conflict, but as its instigator.

The Luddites were a social movement of British textile artisans in the early nineteenth century who protested - often by destroying mechanized looms - against the changes produced by the Industrial Revolution, which they felt were leaving them without work and changing their entire way of life. Since then, the term Luddite has been used derisively to describe anyone opposed to technological progress and technological change.

At a conference, held behind closed doors in Monterey Bay, California, leading researchers warned that mankind might lose control over computer-based systems that carry out a growing share of society's workload, from waging war to chatting on the phone, and have already reached a level of indestructibility comparable with a cockroach.

'These are powerful technologies that could be used in good ways or scary ways,' warned Eric Horvitz, principal researcher at Microsoft. According to Alan Winfield, a professor at the University of the West of England, scientists are spending too much time developing artificial intelligence and too little on robot safety. 'We're rapidly approaching the time when new robots should undergo tests, similar to ethical and clinical trials for new drugs, before they can be introduced,' he said.

Noel Sharkey, professor of artificial intelligence and robotics at Sheffield University, warned that such robots could soon be used for policing, for example during riots such as those seen in London at the recent G20 summit. 'Is this a good thing?' he asked.

Scientists are particularly worried about the way the latest, highly sophisticated artificially intelligent products perform human-like functions. Japanese consumers can already buy robots that 'learn' their owner's behaviour, can open the front door and even find electrical outlets and recharge themselves so they never stop working.

The scientists dismissed as fanciful fears about 'singularity' - the term used to describe the point where robots have become so intelligent they are able to build ever more capable versions of themselves without further input from mankind.

Japan already has robot cleaners and teachers, but now they have been brought in to cook noodles for hungry workers. The mechanical chefs dole out nearly 80 bowls of noodles a day to commuters at the 'Fua-men' ramen noodle shop in the city of Nagoya. The noodle shop, which sells a regular noodle bowl with a pork broth-based soup for around £4, is yet to make a profit, partly due to the large investment in the research and development of the robotic arms.

Economic Growth Given Machine Intelligence by Robin Hanson, School of Public Health, University of California:

Machines complement human labour when they become more productive at the jobs they perform, but machines also substitute for human labour by taking over human jobs. At first, expensive hardware and software does only the few jobs where computers have the strongest advantage over humans. Eventually, computers do most jobs. At first, complementary effects dominate, and human wages rise with computer productivity. But eventually substitution can dominate, making wages fall as fast as computer prices now do.

When robots are capable of fulfilling all menial labour the divide between business owners and labourers will become outrageous. With business owners making total profit off every good produced by cutting out the cost of labour their wealth will sky-rocket while all of their former human labourers plummet into destitution as they find themselves unemployed. Yet the working class is also the consuming class, so if the working class loses its income the business owners lose their consumer market and the economy will collapse.

If it is very difficult for a human to make the killing decision in combat, how can a robot ever be trusted to decide? Unless the robot patrols a black and white battlefield, where anything that is not it or one of it can exist, a robot accompanying human troops in any capacity would be an invitation for friendly fire or collateral damages, something that happens regularly among even human troops. But, human beings are very expensive to train and to maintain. In the end, cost eclipses wisdom.

www.youtube.com/watch?v=cHJJQ0zNNOMPredatory Robots

Robotic unmanned predator drones […] which can seek out and kill human targets, have already moved out of the movie theatres and into the theatre of war in Afghanistan and Iraq. While at present controlled by human operators, they are moving towards more autonomous control.

Cyberknife

The arm of the 'Picasso robot' seen painting cars on an assembly line in a Citröen advert is to be used to treat cancer patients.

A London hospital is the first in the country to buy a Cyberknife robot, a radiotherapy machine based on the same technology.

The device takes X-rays that can pinpoint minuscule tumours hidden deep inside the body, and calculate how much radiotherapy is needed to destroy them. Cameras guide the robotic arm, which delivers a needle-thin beam of radiation at the diseased area. The arm can move in all directions, 'painting' every angle of the cancer with radiation without damaging surrounding tissue. The £3 million device has been bought by the private Harley Street Clinic but will be offered to NHS patients across the country.

www.youtube.com/watch?v=7cJZHtMED5Q