- Manufacturer: Ikea

- Designer: Chris Martin

- Material: wood, plastic composite

- Dimensions: 81 × 48 × 66 cm

- www.ikea.com

Index

- Ambition Ellan, a rocker that […] comes in the signature thin, compact box, and you assemble it at home without any tools or hardware. A $39.99 dining chair th

- Designer Englishman Chris Martin and Swede Magnus Elebäck met ten years ago and have since worked side by side as consultants for the furniture industry. With

- Material The Ellan rocking chair is produced in a composite material consisting of 51% wood residue and 49% plastic. Manufacturing is resource efficient becaus

- Recycling Wood and plastic are like oil and water, and do not mix well. Wood is hydrophilic – it absorbs water – and plastic is hydrophobic, repelling it. A 'co

- Production Mass production (also called flow production, repetitive flow production, series production, or serial production) is the production of large amounts

- Flat Pack Ready-to-assemble furniture (RTA), also known as knock-down furniture or flat pack furniture, is a form of furniture that is purchased in multiple pie

- Manufacturer Ikea is a private company that sells and distributes home products that are low priced with a twist, you put them together yourself. This concept has

- Scandinavian Design Scandinavian design, as we know it today, […] started out as a design movement during the Modern Era, around the 1930s to 1970s. Centre to the design

- Design for All A design philosophy targeting the use of product and services by as many people as possible without the need for adaptation. According to the Europea

Ellan, a rocker that […] comes in the signature thin, compact box, and you assemble it at home without any tools or hardware. A $39.99 dining chair that can rock back on its hind legs without tipping over.

Designer Chris Martin worked with production staff for a year and a half to adapt a wood-fiber composite, an inexpensive blend of wood chips and plastic resin used in highway noise barriers, for use in furnishings. Martin also had to design the chair to break down into six pieces, so it could be flat-packed and snapped together without screws. His cost obsession fuses with the design culture. 'Designing beautiful-but-expensive products is easy,' says Josephine Rydberg-Dumont, president of Ikea of Sweden.

'Designing beautiful products that are inexpensive and functional is a huge challenge.'

Englishman Chris Martin and Swede Magnus Elebäck met ten years ago and have since worked side by side as consultants for the furniture industry. With their accumulated knowledge from these years, they are now taking the next step by producing and marketing their own collection of furniture using a new and simple method for developing products. By taking away the filters normally associated with a producer they can make products that would otherwise get stuck somewhere in the development process. Chris Martin, who used to be Jasper Morrison's right hand man, has designed Massproductions first furniture collection, 'Tio'.

The collection consists of chairs and tables in steel wire that are produced in a computer

controlled bending machine. With just a few steel wires, Chris Martin has designed furniture that catches the eye and attracts the design conscious customer.

'The design for 'Tio' was the end result of a few months of thinking, sketching and sculpting. My point of departure was to arrange a fan of wires into a comfortable seat and then connect them in a straightforward and logical frame, which minimized the amount of steel used. So really the appeal comes from pragmatic thinking, executed within the restraints of the materials characteristics and according to an industrial production process. Sounds clinical, but the result is something I find very pleasing. For those who find steel wires too hard, we have developed an upholstered cushion to give extra comfort during long dining sessions.' says Chris Martin.

The Ellan rocking chair is produced in a composite material consisting of 51% wood residue and 49% plastic. Manufacturing is resource efficient because more than half of the material is recycled. Surprisingly, the composite weighs less than pure plastic with the same mechanical properties, cutting transport expenses and energy consumption.

WPC

Wood-plastic composite (commonly abbreviated as WPC) is a composite material lumber or timber made of recycled plastic and wood wastes.

Manufacturers claim that wood-plastic composite is more environmentally friendly and requires less maintenance than the alternatives of solid wood treated with preservatives or solid wood of rot-resistant species. Resistant to cracking and splitting, these materials can be moulded with or without simulated wood grain details. Even with the wood grain design these materials are still visually easy to distinguish from natural timber as the grains are the same uniform color as the rest of the material.

A major advantage over wood is the ability of the material to be moulded to meet almost any desired spatial conditions. It can also be bent and fixed to form strong arching curves. wood-plastic composites behave like wood and can be shaped using conventional woodworking tools. At the same time, they are moisture-resistant and resistant to rot, although they are not as rigid as wood and may slightly deform in extremely hot weather.

Recycled Composites

Recycled wood/plastic composite lumber is one of the prime uses for recycled plastic trash bags and waste wood fibers. The composite material is used to produce building products such as decking, door and window frames, and exterior mouldings. Manufacturers claim that products produced with recycled wood/plastic lumber are more durable than conventional preservative-treated lumber. Also, these products contain no toxic chemicals such as those used in conventional treated lumber.

Recycled wood/plastic composite lumber typically consists of a 50/50 mix of wood fibers from recovered saw dust and waste plastics that include high-density polyethylene, PVC, and others. The material is formed into both solid and hollow profiles. Recycled wood/plastic composites are typically more rigid than 100 percent recycled plastic lumber because the wood fibers act as reinforcement.

Plastic

Plastic was one of the great innovations of the 20th century, but German scientists believe a new invention, liquid wood, could soon supplant the chemical in terms of everyday usefulness.

Though it has proven to be extremely useful in the modern world, plastic still has a number of negative selling points. It is non-biodegradable and can contain carcinogens and other toxic substances that can cause cancer.

It is also based on petroleum, a non-renewable resource that will soon be harder to come by. Increases in the price of crude oil leads to parallel rises in the price of plastics.

But there is a new chemical invention that could do away with these long-standing concerns. Norbert Eisenreich, a senior researcher and Deputy of Directors at the Fraunhofer Institute for Chemical Technology (ICT) in Pfinztal, Germany, said his team of scientists have come up with a substance that could replace plastic: Arboform - basically, liquid wood.

It is derived from wood pulp-based lignin and can be mixed with a number of other materials to create a strong, non-toxic alternative to petroleum-based plastics, Eisenreich said, as reported by DPA news agency.

Wood and plastic are like oil and water, and do not mix well. Wood is hydrophilic – it absorbs water – and plastic is hydrophobic, repelling it. A 'compatibilizer' typically a polymer that bridges the interface between the wood and plastic in these products, improves stress transfer and increases their strength and stiffness.

The new wood-plastic composites can use very inexpensive plastics such as those found in old carpet fibers – about 4.4 billion pounds of which are now wasted every year, going into landfills where they are extremely slow to biodegrade and pose a significant waste disposal problem. The technology may prompt a major expansion of the wood-plastic composite industry into new types of products and uses, experts say. In particular, such products may help further replace wood treated with chemical preservatives, some of which have already been banned due to health and environmental concerns.

China

Unlike many western nations whose citizens, for the most part, participate in recycling due to a combination of environmental awareness and municipal initiatives, in China the motivation for almost all participants to recycle is purely economic. There are relatively few government or municipal systems for urban collection. On a local level, Chinese citizens scour the streets of cities and villages daily, collecting anything from soda cans and water bottles to old refrigerators, washing machines or simply anything made of metal, paper, wood or plastic. Many collectors use three-wheeled bicycle carts to haul their bounty, stalking high-density residential areas and advertising their arrival by shouting or ringing a bell to alert anyone who might want to part with junk. Recycling is profitable for everyone. Households with unwanted scrap can sell to collectors. The two parties are often seen haggling deals on street corners or in front of homes. Prices are calculated by the amount of resource value embedded in the item. Collected items are dropped off at depots. Often located in the suburbs, these depots have, over the years, grown organically to resemble shantytowns. A hardworking scrap collector in Beijing can earn about $125 to $190 US per month.

On a larger scale, China has become the world's recycler. A resource-hungry economy coupled with an inexpensive, abundant labour force and poorly enforced global rules on waste trade make China the world's choice destination for recyclable materials. Most large scale recycling in China is quite primitive, but there are exceptions. Highly organized corporate operations such as that of Cankun (a.k.a. EUPA), the world's third largest aluminum recycler, have refined the process of recycling into a remarkably efficient industry. Many Chinese businessmen with an established worldwide network of brokers purchase large quantities of material (much of it hazardous) from developed Western and Asian nations then ship it by container vessels to China's eastern and southern ports. Due to the very nature of large-scale recycling, and despite efforts by the central government in Beijing to prohibit the importation of hazardous forms of waste, China faces an environmental and human health cost in the form of deteriorated air, land and water.

Mass production (also called flow production, repetitive flow production, series production, or serial production) is the production of large amounts of standardized products, including and especially on assembly lines. The concepts of mass production are applied to various kinds of products, from fluids and particulates handled in bulk (such as food, fuel, chemicals, and mined minerals) to discrete solid parts (such as fasteners) to assemblies of such parts (such as household appliances and automobiles). […]

Mass production was popularised in the 1910s and 1920s by Henry Ford's Ford Motor Company, which introduced electric motors to the then-well-known technique of chain or sequential production and, in the process, began a new era often called the 'second industrial revolution.' Ford's contribution to mass production was synthetic in nature, collating and improving upon existing methods of sequential production and applying electric power to them, resulting in extremely-high-throughput, continuous-flow mass production, making the Model T affordable and, as such, an instant hit.

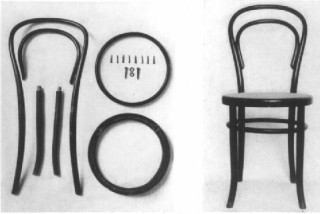

Michael Thonet

The N°14 chair is the most famous chair made by the Thonet chair company. Also known as the bistro chair, it was designed by Michael Thonet in the 19th century using a unique steam bent technology that required years to perfect. With its affordable price and simple design, it became one of the best-selling chairs ever made. Some 50 million N°14s were sold between 1860 and 1930, and millions more have been sold since. Thonet's N° 14 is made of six pieces of steam-bent wood, ten screws, and two nuts. The wooden parts were made by heating beechwood slats to 100 degrees Celsius, pressing them into curved cast-iron molds, and then drying them at around 70 degrees Celsius for 20 hours. The chairs could be mass produced by unskilled workers and disassembled to save space during transportation, an idea similar to flat pack IKEA furniture. The design was a response to a requirement for cafe-style chairs. The seat was often made of woven cane/palm, because the holes in the seat would let spilt liquid drain off the chair. Chair N°14, today known as 214, is still produced by Thonet.

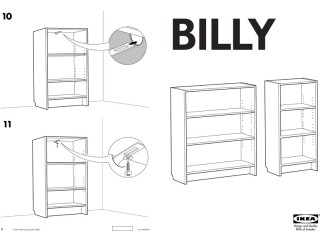

Ready-to-assemble furniture (RTA), also known as knock-down furniture or flat pack furniture, is a form of furniture that is purchased in multiple pieces and requires assembly. This form of furniture generally arrives in a box and contains instructions for the buyer to follow in order to assemble it after purchase. […] Ready-to-assemble furniture is popular among consumers that wish to save money on their furniture purchases by assembling the product on their own and no need for delivery cost. In addition to saving the consumer money, flat pack furniture is generally simple to assemble and requires only the use of simple tools.

Merchants benefit from selling ready-to-assemble furniture because furniture that is already assembled tends to be bulky and more expensive to store and to deliver. Since the furniture does not need to be assembled in the factory, ready-to-assemble furniture is also less expensive for the merchant to purchase. Due to these many factors, selling flat pack furniture is a more cost effective method of conducting business.

Ready-to-assemble furniture is typically packaged in a kit form with the pieces packaged in one or multiple boxes. The kit may contain a number of flat parts, fasteners, screws, fixings, and other parts that are needed to assemble the furniture.

Concept

Ready-to-assemble furniture was first invented by Gillis Lundgren, who was a Swedish draughtsman. Lundgren developed the idea when he needed to fit a table into his car. According to reports, Lundgren broke the legs off his table so he could fit it in the car and then reassembled the table at home. He then discussed the idea with his employers at IKEA and the company later built its entire business around the concept.

Ikea is a private company that sells and distributes home products that are low priced with a twist, you put them together yourself. This concept has taken Ikea to the forefront as a leader in the industry since 1943 when they were created by founder Ingvar Kamprad in Sweden. Ikea furniture is very well known for its modern and easy to assemble design which saves the consumer money[...]

Affordable Goods

The Ikea concept is based on the market positioning statement. 'We do our part' focuses on our commitment to product design, consumer value and clever solutions. By using inexpensive materials in a novel way and minimising production, distribution and retail costs, our customers benefit from low prices. The Ikea vision is 'To create a better everyday life for the many people.'

Our business idea is 'To offer a wide range of well designed, functional home furnishing products at prices so low that as many people as possible will be able to afford them.'

Much of Ikea's furniture is designed to be assembled by the consumer rather than being sold pre-assembled. Ikea claims this permits them to reduce costs and use of packaging by not shipping air; the volume of a bookcase, for example, is considerably less if it is shipped unassembled rather than assembled. This is also a practical point for many of the chain's European customers, where public transport is commonly used; the flat-pack distribution methods allow for easier transport via public transport from the store to a customer's home for assembly.

Ikea contends that it has been a pioneering force in sustainable approaches to mass consumer culture. Kamprad refers to the concept as 'democratic design,' meaning that the company applies an integrated approach to manufacturing and design. […] Not all furniture is stocked at the store level. For example, while a particular color of sofa model may be stocked and can be picked up at the store, another color of the same model that is not available in the store will instead have to be shipped from a warehouse to the customer's home for an additional delivery charge. Unlike with other retail stores, any requests for a model to be shipped from the warehouse to the store for pickup would also incur the same delivery charge to the customer. Delivery charges can easily add another 10% to 25% to the purchase price.

Philosophy

A Furniture Dealer's Testament is Ingvar Kamprad's message to his co-workers. It was written in the mid-70s when the Ikea founder emigrated from Sweden to become a tax exile in Switzerland. Every co-worker should have one: it is the path to truth, the encapsulation of the sacred concept. Kamprad's central ideas are further distilled in The Little Word Book (shades of Mao): humility, strength of will, simplicity, cost awareness, fellowship. The latter is described in Bertil Torekull's authorised history of Ikea, Leading By Design, as 'a kind of catechism; its explanations are in the spirit of Martin Luther's teachings to the faithful.'

As traditional institutions - the Crown, the Church, Parliament, Marks and Spencer - have withered in the UK, Ikea has stepped in to fill the gap. It is more than a store, it is a religion; it is not selling furniture, it is pitching you a dream. 'They have a cultural mission over and above selling furniture,' explains Alan Young, a creative director at St Luke's, Ikea's UK ad agency. 'They want to create a better life for the many. They also want to 'reach good results with small means' [a quote from the Testament], and to achieve that you have to do things very differently.' […]

Kamprad's vision really is religious: the company exists to improve not just the lot of people, but the people themselves. Self-sufficiency is the watchword: you find your own way round the store, choose your goods with minimal assistance from staff, carry them to the check-out and the car, cart them home, and then assemble them yourselves. The company doesn't do this just because it keeps costs (and thus prices) down, but because it is good for you. It makes you a better person. […]

Self-assembly is a form of both divine worship and self-fulfilment: I screw therefore I am. It also saves you money, which in Kamprad's worldview is another way of serving God. 'We tend to put behavioural imperatives into the advertising,' says Young. 'Ingvar and his creation are absolutist.' So absolutist that when the Bristol IKEA was opened last year, people with beards were banned from the store to reduce congestion. (It later transpired that this was a joke, though it is an interesting comment on Ikea's idiosyncratic image that people took it seriously and beardists complained.)

A Furniture Dealer’s Testament

Growth

It is our duty to expand… Those who cannot or will not join us are to be pitied…. Let us continue to be a group of positive fanatics who stubbornly and persistently refuse to accept the impossible, the negative. What we want to do, we can do and will do, together. A glorious future!

Fallibility

Only while sleeping one makes no mistakes.

Use of Time

Divide your life into 10-minute units, and sacrifice as few as possible in meaningless activity.

Simplicity

Bureaucracy complicates and paralyzes! Exaggerated planning is the most common cause of corporate death… We do not need fancy cars, posh titles, tailor-made uniforms, or other status symbols. We rely on our strength and our own will!

Solutions

Expensive solutions to any kind of problem are usually the work of mediocrity. We have no respect for a solution until we know what it costs.

Accomplishment

The feeling of having finished something is an effective sleeping pill. A person who retires feeling that he has done his bit will quickly wither away. A company that feels it has reached its goal will quickly stagnate and lose its vitality.

Happiness

Happiness is not reaching your goal. Happiness is being on the way… The word impossible has been, and must remain, deleted from our dictionary.

Ikea

What is good for our customers is also, in the long run, good for us. This is an objective that carries obligations… The objective must be to encompass the total home environment; that is, to offer furnishings and fittings for every part of the home whether indoors or outdoors… It must reflect our way of thinking by being as simple and straightforward as we are ourselves. It must be durable and easy to live with. It must reflect an easier, more natural, and unconstrained way of life.

Scandinavian design, as we know it today, […] started out as a design movement during the Modern Era, around the 1930s to 1970s. Centre to the design are the modern concepts of practicality, simplification of form, and affordability. These are based on the belief that good design should be made available to everyone, not only to the wealthy few. That's why a lot of designers concentrated on creating everyday domestic items – furniture, fabrics, lighting, and ceramic & glass wares (think Ikea).

[…] These are the same reasons why many people love Ikea products – their designs are straightforward and practical. They use forms and patterns that are unique yet very classic, and most importantly, they are very affordable. Like what Scandinavian designers would say, it's good design for all.

A design philosophy targeting the use of product and services by as many people as possible without the need for adaptation.

According to the European Commission, it 'encourages manufacturers and service providers to produce new technologies for everyone: technologies that are suitable for the elderly and people with disabilities, as much as the teenage techno wizard.'

Closely related to the concepts of Inclusive Design or Universal Design, the origin of Design for All lies in the field of barrier free accessibility for people with disabilities, where, it has been recognised, that this provides benefits to a much larger population.

Autoprogettazione

In 1974, [Enzo Mari] came out with 19 designs for wooden furniture entitled Autoprogettazione. Autoprogettazione (self design) was Mari's collection of designs for furniture you could make yourself with just a hammer using inexpensive, off-the shelf lumber. […] In the 1950's Mari was noticing that mass-produced furniture was starting to change people's tastes away from quality and craftsmanship, so he created simple designs to help reconnect people with how things were made. During his 1974 exhibition he gave out a free catalogue with detailed instructions for making these basic, easy-to-assemble furniture pieces using standardized wooden planks and nails. Anyone (except for factories and dealers) was encouraged to make the furniture, or to make variations on them, and send him a picture. Mari's Autoprogettazione made plans for nine tables, three chairs, a bench, a bookshelf, a wardrobe, and four beds. We especially like the long dining room table.

Furniture as Dialogue

The term 'self-design' is misleading since the word 'design' to the general public now signifies a series of superficially decorative objects. By the word autoprogettazione Mari means an exercise to be carried out individually to improve one's personal understanding of the sincerity behind the project. To make this possible you are guided through an archetypal and very simple technique. Therefore the end product, although usable, is only important because of its educational value. A project for making easy-to-assemble furniture using rough boards and nails. An elementary technique to teach anyone to look at present production with a critical eye.