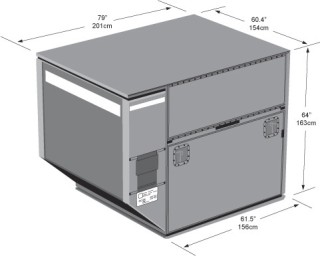

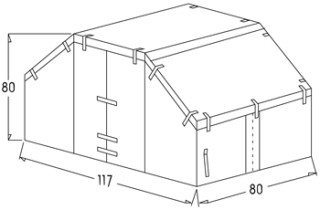

- Manufacturer: PalNet Gmbh

- Material: aluminium alloy

- Dimensions: 192 × 155 × 145 cm

- www.palnet-acp.com

Index

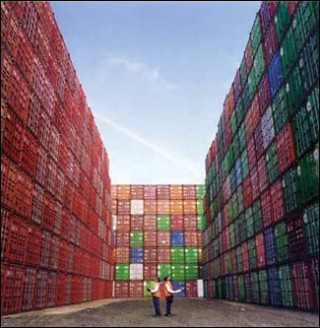

- Cargo Almost all the objects that you can see have at some point been inside a shipping container. In fact, today, 90% of cargo travels by container. Unit L

- Standardisation [Macro error in $entry.abstract: Cannot call method "stripTags" of null (designreal.zip/Chapter/macros.js; line 6)][Macro unhandled: "$entry.abstract"]

- Materials Historically, the material of choice used for the manufacture of air cargo containers has remained aluminium, with no significant new developments occ

- Lifespan The lifespan of a container ranges between 10 to 15 years depending on its level of usage and the conditions it has been exposed to. A well maintained

- Impact Containerization of cargoes is becoming ever more widespread worldwide and almost all products are now transported by container. However, this does no

- Management Nordisk Nordisk is a manufacturer, repair and leasing company of Unit Loading Devices (...) engaged in developing, supplying and supporting ULD equipm

- Airports A cargo aircraft plane (also known as freight aircraft or freighters) is a fixed-wing aircraft designed or converted for the carriage of goods, rather

- Standards Containers are undoubtedly the most successful innovation in the freight transport sector in the last thirty years. Few people have heard of Malcolm M

- Container Types ISO containers are one of the many different types of shipping containers that are available. Containers are basically of two types: standard contain

- Recycling Aluminium recycling is the process by which scrap aluminium can be reused in products after its initial production. The process involves simply re-me

- Other Use Shipping containers have also been used as military training facilities, emergency shelters, school buildings, artists' studios, stores, moveable exhi

Almost all the objects that you can see have at some point been inside a shipping container. In fact, today, 90% of cargo travels by container.

Unit Load Device

A container used to load luggage, freight, and mail on wide-body aircraft and specific narrow-body aircraft. It allows a large quantity of cargo to be bundled into a single unit. ULD containers, also known as cans and pods, are closed containers made of aluminum or combination of aluminum (frame) and Lexan (walls).

The term Unit Load Device (ULD) means any type of container with an integral pallet, or aircraft pallet whether or not owned by an IATA member, and whether or not considered to be aircraft equipped.

Indentification

All ULDs are identified by their ULD number. A three-letter prefix identifies its type, followed by a 4 or 5 digit serial number to uniquely identify it from others of the same type, and ending with a two character:

For example, AKN 12345 DL means that the ULD is a forkliftable LD3 with the unique number 12345 and its owner is Delta Air Lines.

LD3s and LD2s occupy half the width of the cargo bin of the aircraft they are designed for, therefore are loaded two at a time, side-by-side.

Management

A unit load combines individual items or items in shipping containers into a single "unit" that can be moved easily with pallet jack or forklift truck. A unit load packs tightly into warehouse racks, intermodal containers, trucks, and boxcars, yet can be easily broken apart at a distribution point, usually a distribution center, wholesaler, retail store, etc.

www.youtube.com/watch?v=fQ0EnpWRezIContainerization [...] a system of intermodal freight transport using standard intermodal containers that are standardised by the International Organization for Standardization (ISO). These can be loaded and sealed intact onto container ships, railroad cars, planes, and trucks.The introduction of containers resulted in vast improvements in port handling efficiency, thus lowering costs and helping lower freight charges and, in turn, boosting trade flows. Almost every manufactured product humans consume spends some time in a container.

Although having its origins in the late 1780s or earlier, the global standardisation of containers and container handling equipment was one of the important innovations in 20th century logistics.

During the first twenty years of growth containerization meant using completely different and incompatible container sizes and corner fittings from one country to another. The standard sizes and fitting and reinforcement norms that exist now evolved out of a series of compromises among international shipping companies, European railroads, U.S. railroads, and U.S. trucking companies. Four important ISO (International Organization for Standardization) recommendations standardised containerization globally.

Containerization has revolutionized cargo shipping.

Most economic studies of containerization merely assumed that shipping companies would begin to replace older forms of transportation with containerization, but did not predict that the process of containerization itself would have some influence on producers and the extent of trading.

Risks

Containerization increases the fuel costs of transport and reduces the capacity of the transport as the container itself must be shipped around not just the goods. For certain bulk products this makes containerization unattractive. For most goods the increased fuel costs and decreased transport efficiencies are currently more than offset by the handling savings.

Containers have been used to smuggle contraband. The vast majority of containers are never subjected to scrutiny due to the large number of containers in use.

Historically, the material of choice used for the manufacture of air cargo containers has remained aluminium, with no significant new developments occurring for close to thirty years. Traditional aluminium containers have a number of drawbacks. Aluminium containers suffer from durability issues, high maintenance/repair cost and other drawbacks include a low resistance to denting and a tendency to tear when punctured resulting in dangerous, sharp and jagged edges which can present significant safety hazards for handlers and aircraft fuselage body.

Issues

- Damaged containers are piled up as junk at airports occupying extensive and extremely expensive aircraft storage space and posing safety hazards.

- When damaged, the whole container must be transported to the repair site thus causing considerable expenses for repair and carrying it back. Further transportation costs are due to transfer of empty containers from one airport to another, depending on the various volumes.

- The containers are usually preloaded with freight/passengers' luggage to reduce the time required to load an airplane and to ensure all the available space is fully utilised. [...]

- To support all transported containers, the spare ULDs must be ready for use at each stop on the designated route of the aircraft.

Polypropylene

In order to solve many of the problems experienced by the air cargo industry with traditional ULDs, AIRGO developed a lightweight collapsible container. [...] Extruded polypropylene is [...] specifically designed for repeated bending and will not easily tear. [...] [It] is very lightweight compared to fiberglass reinforced plastic, aluminium, or polycarbonate. As a result AIRGO's ULD, with the aluminium pallet and net, weighs approximately forty percent less than the traditional non-collapsible ULD on the market today. [...] This weight savings can mean fuel savings to the airline or increased revenue for additional cargo. Including the cost of the pallet and net, an AIRGO ULD sells for approximately 60 percent of the cost of a non-collapsible ULD.

Durability

DuraWall-ULD containers are designed with an advanced lightweight thermoplastic structural material system that is formed into a continuous shell. This unique combination of continuous fiber fiberglass in a thermoplastic matrix is extremely rugged and demonstrates excellent impact resistance with good mechanical characteristics.

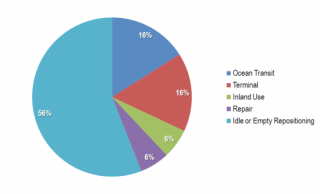

The lifespan of a container ranges between 10 to 15 years depending on its level of usage and the conditions it has been exposed to. A well maintained container [...] can even have a lifespan up to 20 years. Still, a container can spend on average 56% of its lifespan either idle or being repositioned while empty. This represents a non revenue generating part involving additional costs (such as warehousing and repositioning) that are assumed either by the shipping or the leasing company. Such a cost is thus part of the leasing rate. Growing trade imbalances can have a notable impact as more containers will spend additional time idle or being repositioned.

Inspection

In general, any container used for international transport must have a valid safety approval plate or "CSC plate". CSC is the abbreviation for Container Safety Convention. In order to avoid damage in transit, the container should, however, be properly inspected before and after packing.

www.youtube.com/watch?v=L1nZNIeF2ucMaintenance

ULD maintenance is another major problem in the air cargo industry. ULDs are regulated by the Federal Aviation Administration. Therefore, when they are damaged, which is quite often, they must be taken out of service and repaired. The major air cargo companies spend millions of dollars each year in transporting and repairing damaged ULDs.

Equipment weight is a major concern for all airlines. Any weight savings on commercial aircraft can be directly translated into fuel cost savings and/or increased revenue by taking on additional cargo. Another problem frequently sighted by air cargo ULD Control Managers is the increased demand for ULDs during their peak season: October through December. There is a significant cost associated with purchasing and storing containers for use during the peak season.

ULD imbalances are a problem throughout the industry. Imbalances occur when there are too many ULDs in one airport and not enough in another. In order to correct these imbalances, ULDs have to be shipped empty to their desired location.

Surplus

There are countless numbers of empty, unused shipping containers around the world just sitting on the shipping docks and taking up space. [...] It's just cheaper to buy new containers [...]. The result is an extremely high surplus of empty shipping containers.

Logistics

ULDs might, for instance, be loaded up with freight in Asia and flown to an airport in Europe or the US. If the airline does not have anything to transport at the other end, it must either fly the containers back empty or put the ULDs into storage for the time being. Either way there are high costs involved, especially considering that the ULDs are likely to be urgently needed somewhere else in the world.

Also, airlines frequently have no clear view about the extent or location of containers or the level of their need for them. [...] The airlines are trying to beat these problems with more quality and organizational input. But this does not bring the costs down as much as they would like. More quality means more and more expense.

Globalisation

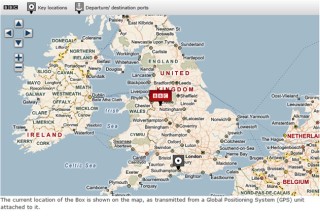

The BBC Box has arrived back in the UK after more than a year travelling the globe by road, rail and sea. The shipping container has carried a variety of contents from whisky and car parts to tinned cat food as part of a project to tell the story of global trade in the current economic climate. BBC Business editor Jeremy Hillman says the journey has helped shed light on issues ranging from the growing strength of China's consumer class to international piracy and what globalisation really means close up. 'Perhaps my favourite story was that of Copenhagen Express Captain Sanjeev Kaushal who only found out about the BBC Box, and that he was carrying it on his own ship, from relatives e-mailing him on board', he said.

Containerization of cargoes is becoming ever more widespread worldwide and almost all products are now transported by container. However, this does not mean that the risks which arise during transport are consequently a thing of the past. The cargoes in containers are still exposed to climatic, biological and chemical stresses, such that the causes of losses which previously occurred in the hold still come about with container transport. If transport is to pass off without loss, selection of a suitable container type is fundamental. However, disparities in the flow of goods mean that suitable containers are not always available, so increasing the significance of cargo care during transport.

'Nobody wants to know about ULDs … until there are none…' Famous quote from many ULD managers.

Repair and Maintenance of ULDs costs the industry US$ 220 million per year. High incidence of damage, forces airlines to create large inventory buffers.

Despite the recent truce on high fuel costs, lightweight ULDs remain on everyone's mind, whilst there is a need for change, the big question many are facing is how to finance the change.

At a time of globalised markets, the pressure of competition throughout the private sector has become extremely heavy. The air travel industry is no exception and has been hit particularly hard – what used to be friendly competition has turned into a bitter battle for passengers and freight. This development seems set to grow in the immediate future.

The airfreight and passenger markets have experienced strong growth for two decades. Air cargo traffic is projected to rise by more than 6% per year and passenger traffic nearly 5% per year from now until 2024. In fact, by 2024, the worldwide fleet is expected to grow to more than 35,000 air cargo and passenger jets, which will have a significant impact on the need for more ULDs (Unit Load Devices). Ironically, this industry growth comes at a time when airlines are under substantial pressure to reduce costs.

As well as reducing costs, increasing flexibility is also important. Only having to pay for costs when airlines actually use a particular service makes that service much more economically viable. But pay per use also means that there are no fixed costs for the ULD itself or its storage, maintenance and the like.

Nordisk

Nordisk is a manufacturer, repair and leasing company of Unit Loading Devices (...) engaged in developing, supplying and supporting ULD equipment for the commercial passenger and air freight/cargo airline industry as well as the military, including its engineering support, and Worldwide Service Network. [...] There are an estimated 600,000 containers in service in the fleet today with approximately 40,000 new units sold each year. Each unit has an average useful life of about 5 years, and [...] the total number of units in service will continue to rise over the next 10 years.

Nordisk Aviation Products [...] is helping airlines around the world reduce both harmful environmental emissions and fuel consumption through the company's lightweight cargo containers. Nordisk projects that innovative lightweight air cargo containers, or ULDs can help customers reduce annual carbon dioxide (CO2) emissions by up to 438 million tons and can save as much as $117 million USD in fuel expenses in a year. Nordisk estimates that if every airline around the world takes advantage of these lightweight container technologies, they could save more than 400,000 tons of CO2 annually in addition to $120 million USD in fuel costs each year, based on fuel at US$ 0.80 per kg.

Satco

Satco, Inc. is the leader in the engineering, design, manufacture and maintenance of unit load devices (ULDs) worldwide. On any given day at least seven million express air freight packages and envelopes are shipped in Satco ULDs throughout the world.

Unitpool

Unitpool is the only independent ULD pooling company in the world. Outsourcing ULD management to Unitpool eliminates capital expenditure and the risks of ULD ownership, saves on operating costs, and improves management and utilization of the ULD fleet.

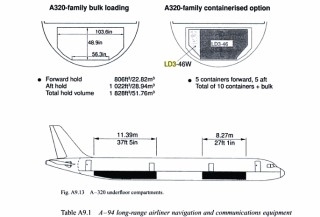

A cargo aircraft plane (also known as freight aircraft or freighters) is a fixed-wing aircraft designed or converted for the carriage of goods, rather than passengers. They are usually devoid of passenger amenities, and generally feature one or more large doors for the loading and unloading of cargo. [...]

Aircraft designed for cargo flight use have a number of features that distinguish them from conventional passenger aircraft: a "fat" looking fuselage, a high-wing to allow the cargo area to sit near the ground, a large number of wheels to allow it to land at unprepared locations, and a high-mounted tail to allow cargo to be driven directly into and off the aircraft. Aircraft were put to use carrying cargo in the form of air mail as early as 1911. Although the earliest aircraft were not designed primarily as cargo carriers, by the mid 1920's airplane manufacturers were designing and building dedicated cargo aircraft. Most conversions are carried out on older aircraft no longer suitable for passenger use, often due to changing safety or noise requirements, or when the aircraft type is considered to have become uncompetitive in passenger airline service, but there is also a market for new-build freighter designs.

Air Freight Industry Structure

The industry consists of a number of different commercial organisations who provide shippers with through freight services. These organisations, mainly within the private sector, operate in a highly competitive environment.

Airports: generally the airports act as landlords and infrastructure providers charging landing fees and stand rentals or parking fees to airlines (their main customers) and charging rent to service companies for passenger reception terminals, retail and catering outlets offices, cargo transit sheds, air craft maintenance work shops etc.

Airlines: the suppliers of air cargo capacity [...] are either scheduled operators, charter operators, freighter operators or integrated carriers. [...] Freighter operators are the operators of freight only aircraft.

Containers are undoubtedly the most successful innovation in the freight transport sector in the last thirty years.

Few people have heard of Malcolm McLean, yet his invention, which lay the foundation for ISO's international standards on freight containers, revolutionized the world economy of the 20th century. Malcolm McLean's great achievement was to develop the first secure, reliable, and cost-effective means of transporting cargo: the shipping container. Distilled into international standardization [...] his insight changed world trade dramatically.

The lack of a single international standard for pallets causes substantial continuing expense in international trade. A single standard is difficult because of the wide variety of needs a standard pallet would have to satisfy: passing doorways, fitting in standard containers, and bringing low labor costs.

More than five million freight containers are now in service throughout the world. [...] To date, over twenty International Standards have been developed. They cover terminology, classification, dimensions, specifications, test methods of series 1 freight containers (including containers for general purposes, thermal containers, tank containers for dry bulk, platform and platform-based containers) and of air/surface (intermodal) general purpose containers. The standards also deal with the handling and securing of containers, their coding, identification and marking, information related to containers onboard vessels, container equipment data exchange (CEDEX), etc.

ISO containers are one of the many different types of shipping containers that are available. Containers are basically of two types:

- standard containers, also referred to as ISO containers or intermodal containers;

- non standard shipping containers;

The ISO or intermodal rated containers conform to the International Organization for Standardization (ISO) container manufacturing standards.

ISO containers are used to transport freight. They can be used to transport freight in more than one mode: truck and rail or rail and ship. That's why they are also referred to as intermodal containers.

An intermodal container or freight container (commonly shipping container) is a reusable transport and storage unit for moving products and raw materials between locations or countries; the terms container or box may be used on their own within the context of shipping. Containers manufactured to ISO specifications may be referred to as ISO containers and the term high-cube container is used for units that are taller than normal. There are approximately seventeen million intermodal containers in the world and a large proportion of the world's long distance freight generated by international trade is transported inside shipping containers. The containerization system developed from a design of an [...] 2.438 m cube (2.44 m°—2.44 m°—2.44 m) units used by the United States' military and later standardised by extension to [...] 3.05 m, 20-foot (6.10 m), and 40-foot (12.19 m) lengths.

Container variants are available for many different cargo types. Non-container methods of transport include bulk cargo, break bulk cargo and tankers/oil tankers used for liquids. For air freight the alternative and lighter IATA defined Unit Load Device is used.

Variations on the standard container exist for use with different cargoes including refrigerated container units for perishable goods, tanks in a frame for bulk liquids, open top units for top loading and collapsable versions. Containerised coal carriers, and 'bin-liners' (containers designed for the efficient road/rail transportation of rubbish from cities to recycling and dump sites) are used in Europe.

A shipping container is a container with strength suitable to withstand shipment, storage, and handling. Shipping containers range from large reusable steel boxes used for intermodal shipments to the ubiquitous corrugated boxes.

Types of shipping container

- Intermodal freight containers

- Corrugated box

- Wooden box

- Crate Intermediate bulk shipping container

- Drum

- Insulated shipping containers

- Unit load device

- Specialized shipping containers

Container Types

- Collapsible ISO

- Flushfolding flat-rack containers for heavy and bulky semi-finished goods, out of gauge cargo

- Gas bottle

- Generator

- General purpose dry van for boxes, cartons, cases, sacks, bales, pallets, drums in standard, high or half height

- High cube palletwide containers for europallet compatibility

- Insulated shipping container

- Refrigerated containers for perishable goods

- Open top bulktainers for bulk minerals, heavy machinery

- Open side for loading oversize pallet

- Platform or bolster for barrels and drums, crates, cable drums, out of gauge cargo, machinery, and processed timber

- Rolling floor for difficult to handle cargo

- Swapbody

- Tank containers for bulk liquids and dangerous goods

- Ventilated containers for organic products requiring ventilation

Aluminium recycling is the process by which scrap aluminium can be reused in products after its initial production. The process involves simply re-melting the metal, which is far less expensive and energy intensive than creating new aluminium through the electrolysis of aluminium oxide (Al2O3), which must first be mined from bauxite ore and then refined using the Bayer process. Recycling scrap aluminum requires only 5% of the energy used to make new aluminium. For this reason, approximately 31% of all aluminium produced in the United States comes from recycled scrap.

A common practice since the early 1900s and extensively capitalized during World War II, aluminium recycling is not new. It was, however, a low-profile activity until the late 1960s when the exploding popularity of aluminium beverage cans finally placed recycling into the public consciousness.

Sources for recycled aluminium include aircraft, automobiles, bicycles, boats, computers, cookware, gutters, siding, wire, and many other products that require a strong light weight material, or a material with high thermal conductivity. As recycling does not damage the metal's structure, aluminium can be recycled indefinitely and still be used to produce any product for which new aluminium could have been used.

The aluminium recycling industry has invested hundreds of millions of dollars developing a system of more than 10,000 recycling centers nationwide. (...) In 1972, 24,000 metric tons of aluminium used beverage cans (UBCs) were recycled. By 2006, this had grown to over 525,000 metric tons.

It's Not Just About Cans. While cans are the most visible part of the aluminum recycling story, they are far from the whole story. In fact, can recycling typically amounts to less than 30 percent of the tonnage of aluminum consumer products that are recycled.

Advantages

The recycling of aluminium generally produces significant cost savings over the production of new aluminium even when the cost of collection, separation and recycling are taken into account. Over the long term, even larger national savings are made when the reduction in the capital costs associated with landfills, mines and international shipping of raw aluminium are considered.

The environmental benefits of recycling aluminium are also enormous. Only around 5% of the CO2 is produced during the recycling process compared to producing raw aluminium (and an even smaller percentage when considering the complete cycle of mining and transporting the aluminium). Also, open-cut mining is most often used for obtaining aluminium ore, which destroys large sections of the world's natural land. Recycling aluminium cans saves approximately 80% of the energy required to make aluminium cans from virgin materials.

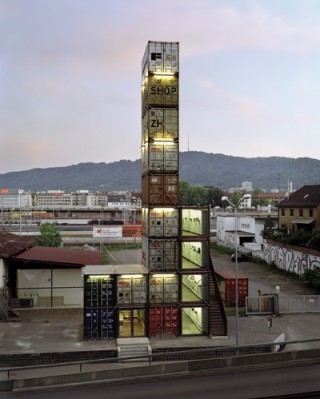

Shipping containers have also been used as military training facilities, emergency shelters, school buildings, artists' studios, stores, moveable exhibition spaces on rails, medical clinics, radar stations, abstract art, transportable factories, experimental labs, workshops, house Foundations on unstable seismic zones, elevator/stairwell shafts.

Steel shipping containers outlive their usefulness as cargo carriers within 5 years, and they used to sit abandoned at shipyards for years. Now, they're gaining increasing recognition for their durability, adaptability, light weight, low cost and ease of stacking, spurring a recycling trend that has resulted in shipping container sculpture, homes, hotels, museums and more. The possibilities are seemingly endless [...].

Containers can be transformed into stylish modern homes that are expandable, and the space that you get is much the same as in many swanky developments.

Containers are some of the most available and simplest of all systems and they are both a solution to today's urban housing problems and a sensible way to recycle industrial products. They are relatively cheap, adaptable, durable, transportable, stackable, light and reusable.

The concept of using shipping containers as buildings is not new. The military have been using the structures as temporary offices, bunk houses and showers for some time. Examples of designers incorporating shipping containers into residential designs date back to the 1980s.

Containers are an extremely flexible method of construction, being both modular in shape, extremely strong structurally and readily available. Container Cities offer an alternative solution to traditional space provision.

With the green theme growing in popularity across every stretch of the world, more and more people are turning to cargo container homes for green alternatives for office, and even new home, construction.

In 2000, the firm Urban Space Management completed the project called Container City [...] in London. [...] In 2006, the Dutch company Tempohousing finished in Amsterdam the biggest container village in the world: 1,000 student homes from modified shipping containers from China.

The biggest shopping mall or organized market in Europe is made up of alleys formed by stacked containers, on 170 acres (69 ha) of land [...] in Odessa, Ukraine. Informally named "Tolchok" and officially known as the Seventh-Kilometer Market.